2017 China New Design Rubber Molded Gasket - ZF6 lead glass – Golden Door Detail:

Radiation shielding lead glass for nuclear applications

High PB Lead glass for Nuclear Industry, model ZF6 ,are mainly used in nuclear power station and nuclear reactor, whose density is 4.78 g/cm3, lead equivalent is 0.40mmpb and light transmittance rate is more than 85%. This high PB Lead glass produced by our company can reach to 120mm thickness.

Our quality standard specifies that “no visible bubbles, inclusions, scratch or sleeks, or vein are allowed by observation at one meter distance”.

Technical data

Product lead glass

Model ZF6

Density 4.78 gm/cm3

Thickness 20mm ~ 120mm

Lead equivalence 0.40mm Pb for Gamma rays

Lead glass dimensions

1000mm x 800mm

1200mmx 1000mm

1500mmx 1000mm

1500mmx 1200mm

Optional

Lead Lined Window Frames

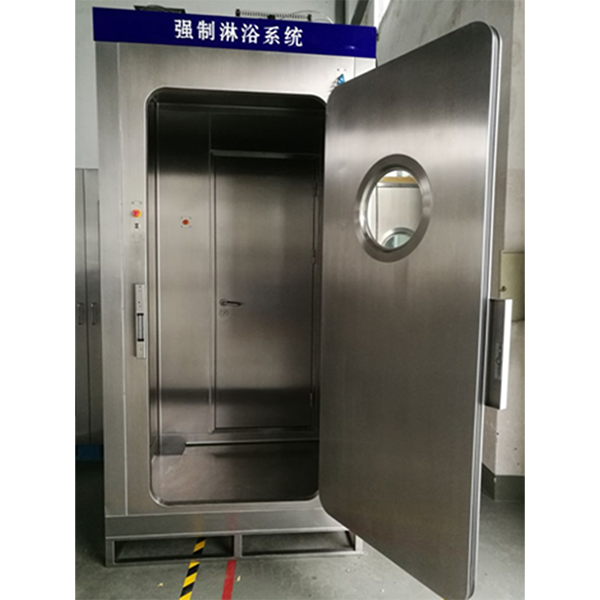

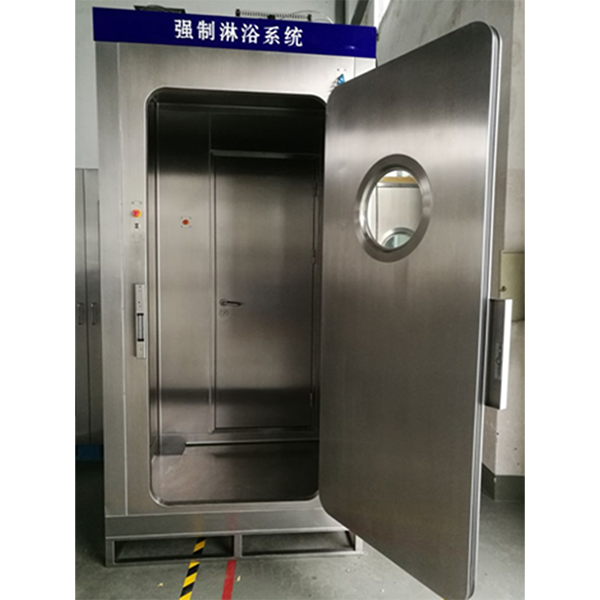

Product detail pictures:

Related Product Guide:

50 stunning photos reveal what microkitchens are like in New York and San Francisco | Air Shower For Laboratory

Photos: The week’s worst restaurant inspections in Jacksonville (Oct. 22) – The Florida Times-Union | Sliding Freezer Doors

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for 2017 China New Design Rubber Molded Gasket - ZF6 lead glass – Golden Door, The product will supply to all over the world, such as: Doha, Salt Lake City, Ukraine, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

-

Factory Price Door Fingers Emi Shielding Spring...

-

China Supplier 6 Settings Adjustable Hand Showe...

-

Lowest Price for Sus 304 Pass Box - BSL3 Level...

-

Manufacturer of Bathroom Showerheads - Automat...

-

Manufacturer for Illuminated Makeup Mirror - W...

-

OEM/ODM China Portable Toilet And Shower Room -...